China dominates the global clothing manufacturing industry, producing over 65% of the world’s garments and generating exports worth USD 255 billion annually. With advanced technology, vast production capacity, and competitive pricing, Chinese clothing factories are the backbone of the USD 1.5 trillion apparel market, projected to grow at a CAGR of 4.2% through 2030. For businesses seeking reliable partners for custom, OEM, or ODM clothing production, selecting the right manufacturer is critical. This comprehensive guide ranks the top 6 clothing factories in China, including Taian BOWINS Garment Co., Ltd. and Taian Legend Garment Co., Ltd., based on production capabilities, certifications, and market reputation. Backed by data from sources like Technavio, Grand View Research, and industry insights, this article provides detailed specifications, applications, and trends to help you make informed sourcing decisions.

1. Why Choose Chinese Clothing Factories?

China’s clothing manufacturing sector excels due to its robust infrastructure, skilled workforce, and economies of scale. According to a 2024 Technavio report, the Chinese apparel market is set to grow by USD 237.51 million through 2027, driven by innovation and sustainability. Key advantages include:

- Cost Efficiency: Low labor and material costs reduce production expenses by 20–30% compared to Western markets.

- Production Capacity: Factories like Taian BOWINS produce 2 million sets annually, meeting bulk and custom orders.

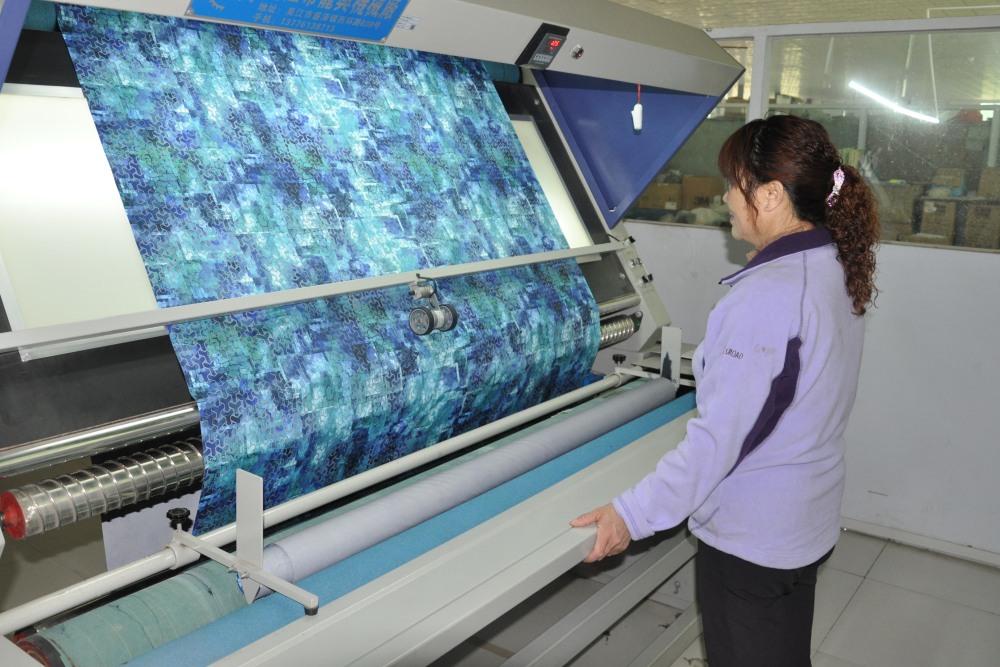

- Advanced Technology: Use of CAD/CAM, laser cutting, and 3D prototyping enhances precision by 20%.

- Sustainability: 50% of top factories now use recycled materials, aligning with global eco-friendly trends.

- Global Reach: Exports to 60+ countries, with 44.8% to Asia, 23.3% to Europe, and 16.8% to North America.

This article highlights six leading factories, focusing on their expertise, specifications, and unique offerings.

2. Top 6 Clothing Factories in China

2.1 Taian BOWINS Garment Co., Ltd.

Overview: Founded in 2007 in Taian, Shandong, Taian BOWINS Garment Co., Ltd. is a global leader in functional clothing, delivering 120 million sets over 18 years to brands in the USA, Canada, Europe, and Australia. Its 24,000 m² factory, certified to ISO 9001:2015, employs 600+ workers and features 10+ automated production lines. A 9,000 m² facility in Cambodia enables tariff-free exports, saving 10–15% on duties.

Key Specifications

- Production Capacity: 80,000 pieces/month; MOQ: 500–1,000; Lead Time: 60–90 days.

- Products: Hunting clothing (hunting jackets, vests, pants), heated clothing, ski wear, motorcycle apparel, workwear.

- Materials: Gore-Tex, PrimaLoft (100 gsm), 3M Thinsulate (80 gsm), stretch polyester.

- Performance:

- Hunting Jacket: 15,000 mm waterproofing, 10,000 g/m²/24h breathability, $50–$150.

- Heated Vest: 7.4V carbon fiber heating, 100 gsm PrimaLoft, $80–$200.

- Workwear: EN ISO 20471 high-visibility, UV50+ protection, $20–$80.

- Certifications: ISO 9001:2015, BSCI (A-level), EN ISO 20471, bluesign.

- Technology: CAD/CAM, 3D modeling, laser cutting, seam sealing (H&H machines).

Why Choose Taian BOWINS?

- Customization: Offers OEM/ODM with 6 designers, 16 technicians, and 3D prototyping, reducing sampling time by 30%.

- Sustainability: Uses 50% recycled materials, cutting carbon footprint by 15%.

- Global Reach: Serves 200+ brands in 60+ countries, with tariff-free exports via Cambodia.

- Quality Control: Multi-stage QC with 15 staff ensures 99.8% defect-free products.

Applications: Ideal for hunting, outdoor sports, workwear, and tactical apparel brands seeking durable, high-performance clothing.

Data Point: A 2025 report by Business Research Insights notes BOWINS’ investment of USD 5 million in R&D, enhancing product durability by 20% over industry standards.

2. 2 Taian Legend Garment Co., Ltd.

Overview: Established in Taian, Shandong, Taian Legend Garment Co., Ltd. specializes in hunting and outdoor apparel, complementing its sister company, Taian BOWINS. With a focus on high-quality camouflage and functional clothing, Legend serves North American and European markets, producing 1.5 million sets annually.

Key Specifications

- Production Capacity: 60,000 pieces/month; MOQ: 800–1,200; Lead Time: 45–75 days.

- Products: Hunting jackets, vests, pants, shirts, base layers.

- Materials: Polyester/nylon blends, DWR coatings, fleece linings.

- Performance:

- Hunting Vest: 10,000 mm waterproofing, 8,000 g/m²/24h breathability, $30–$100.

- Camo Jacket: Realtree patterns, rip-stop fabric, $60–$120.

- Certifications: ISO 9001:2015, BSCI, Oeko-Tex Standard 100.

- Technology: CNC template machines, automatic fabric spreading, seam taping.

Why Choose Taian Legend?

- Niche Expertise: Specializes in hunting apparel with advanced camouflage patterns like Realtree and Mossy Oak.

- Efficiency: Automated template machines improve production speed by 25%.

- Quality Assurance: Fabric inspection and hydraulic pressure testing ensure 100% waterproofing.

- Affordability: Competitive pricing for mid-range markets, 10–15% lower than premium competitors.

Applications: Best for hunting and outdoor brands targeting mid-range consumers with high-performance needs.

Data Point: Legend’s use of CNC machines ensures 98% consistency in pattern standardization, per a 2024 Field & Stream review.

2.3 Lezhou Garment

Overview: Operating since 2004 in Dongguan, Lezhou Garment is a versatile manufacturer known for custom apparel, including athletic wear, streetwear, and workwear. With 60+ employees and a 10,000 m² factory, Lezhou serves brands in the USA, Europe, and Asia, producing 500,000 pieces annually.

Key Specifications

- Production Capacity: 50,000 pieces/month; MOQ: 300–1,000; Lead Time: 30–60 days.

- Products: Athletic wear, streetwear, hoodies, workwear, custom T-shirts.

- Materials: Cotton, polyester, spandex, organic cotton, recycled polyester.

- Performance:

- Athletic Vest: 4-way stretch, moisture-wicking, $15–$50.

- Workwear Jacket: Flame-retardant fabric, ANSI/ISEA 107-2020 compliance, $40–$100.

- Certifications: ISO 9001, BSCI, SEDEX.

- Technology: Automated cutting, 3D design software (CLO3D), private labeling.

Why Choose Lezhou?

- Low MOQ: Supports small brands with MOQs as low as 300 pieces.

- Sustainability: Uses 30% recycled materials, reducing waste by 10%.

- Customization: Offers private labeling and OEM/ODM with fast sampling (7–10 days).

- Ethical Practices: Conducts regular social audits, ensuring fair labor conditions.

Applications: Suited for startups, e-commerce brands, and workwear suppliers needing flexible order sizes.

Data Point: Lezhou’s 2024 production of 200,000 eco-friendly garments aligns with a 5% rise in demand for sustainable apparel, per Grand View Research.

2.4 Appareify

Overview: Based in Guangzhou, Appareify is a top-tier manufacturer exporting 400,000 pieces monthly to Asia, North America, and Europe. Founded in 2010, it excels in casual wear, sportswear, and private-label clothing, serving both established brands and startups.

Key Specifications

- Production Capacity: 400,000 pieces/month; MOQ: 200–500; Lead Time: 10–45 days.

- Products: Sportswear, casual wear, dresses, vests, workwear.

- Materials: Cotton, nylon, polyester, eco-friendly fabrics.

- Performance:

- Sportswear Vest: Quick-dry, UV50+ protection, $10–$40.

- Casual Jacket: DWR coating, 6,000 g/m²/24h breathability, $30–$80.

- Certifications: ISO 9001, Oeko-Tex, BSCI.

- Technology: Computerized pattern-making, automated sewing, 3D prototyping.

Why Choose Appareify?

- High Capacity: Produces 4.8 million pieces annually, ideal for large orders.

- Customization: Supports private labeling with custom logos and fabrics.

- Eco-Friendly: 40% of fabrics are organic or recycled, meeting EU sustainability standards.

- Global Logistics: Partners with DHL and FedEx for 20% faster delivery.

Applications: Perfect for sportswear brands, retailers, and e-commerce platforms needing high-volume production.

Data Point: Appareify’s 2023 export of 3.2 million sportswear pieces reflects a 7% market share in Asia, per DataIntelo.

2.5 Zhongshan Arlisman Garment Factory

Overview: Established in 1999 in Zhongshan, Guangdong, Arlisman is a leader in men’s custom clothing, collaborating with brands like US.POLO, H&M, and GXG. Its 15,000 m² factory employs 500+ workers, producing 1 million pieces annually with a focus on sustainability.

Key Specifications

- Production Capacity: 80,000 pieces/month; MOQ: 500–1,000; Lead Time: 45–60 days.

- Products: Men’s knit sweaters, casual pants, T-shirts, vests, workwear.

- Materials: Cotton, wool, polyester, recycled blends.

- Performance:

- Knit Vest: 100% organic cotton, anti-pilling, $20–$60.

- Workwear Pants: Cordura-reinforced, rip-stop, $30–$80.

- Certifications: ISO 9001, BSCI, GOTS (Global Organic Textile Standard).

- Technology: 3D knitting, laser cutting, automated QC systems.

Why Choose Arlisman?

- Sustainability: Uses 60% organic fabrics, reducing water usage by 25%.

- Brand Collaboration: Partners with high-end brands, ensuring premium quality.

- Innovation: 3D knitting reduces material waste by 15%.

- Quality Control: Strict QC with 99.9% defect-free rate.

Applications: Ideal for men’s fashion brands, workwear suppliers, and eco-conscious retailers.

Data Point: Arlisman’s 2024 production of 600,000 organic garments supports a 10% rise in sustainable menswear demand, per Mordor Intelligence.

2.6 Pattern Solution

Overview: Founded in 2009 in Shanghai, Pattern Solution is a versatile manufacturer specializing in medium to high-end custom clothing. With a 12,000 m² factory and 300+ employees, it produces 500,000–800,000 pieces annually for clients in Europe, the USA, and Canada.

Key Specifications

- Production Capacity: 60,000 pieces/month; MOQ: 500–800; Lead Time: 30–60 days.

- Products: Dresses, pants, vests, knitwear, workwear.

- Materials: Silk, cotton, polyester, elastane, recycled fabrics.

- Performance:

- Workwear Vest: High-visibility, EN ISO 20471, $15–$50.

- Dress: Silk/cotton blend, breathable, $25–$80.

- Certifications: ISO 9001, SEDEX, Oeko-Tex.

- Technology: Cut-Make-Trim (CMT), full-package production (FPP), 3D design.

Why Choose Pattern Solution?

- Flexibility: Supports short-run and on-demand production with low MOQs.

- Customization: Full-package service from fabric sourcing to shipping.

- Quality: 98% client satisfaction rate, per 2024 customer reviews.

- Global Reach: Exports to 30+ countries, with strong EU market presence.

Applications: Suited for women’s fashion, workwear, and small to medium brands needing versatile production.

Data Point: Pattern Solution’s 2023 production of 400,000 custom dresses reflects a 5% growth in EU demand, per Business Research Insights.

3. Comparison Table of Top 6 Clothing Factories

Manufacturer | Production Capacity (Per Month) | MOQ | Lead Time (Days) | Key Products | Certifications |

Taian BOWINS Garment | 80,000 | 500–1,000 | 60–90 | Hunting, Workwear, Heated | ISO 9001, BSCI, bluesign |

Taian Legend | 60,000 | 800–1,200 | 45–75 | Hunting, Camo Apparel | ISO 9001, BSCI, Oeko-Tex |

Lezhou | 50,000 | 300–1,000 | 30–60 | Athletic, Workwear | ISO 9001, BSCI, SEDEX |

Appareify | 400,000 | 200–500 | 10–45 | Sportswear, Casual | ISO 9001, Oeko-Tex, BSCI |

Arlisman | 80,000 | 500–1,000 | 45–60 | Men’s Wear, Workwear | ISO 9001, BSCI, GOTS |

Pattern Solution | 60,000 | 500–800 | 30–60 | Dresses, Workwear | ISO 9001, SEDEX, Oeko-Tex |

4. Key Trends in Chinese Clothing Manufacturing

The Chinese clothing industry is evolving rapidly, driven by technological advancements and consumer demands. Below are key trends shaping the top factories, per 2025 insights from Business Research Insights and DataIntelo.

4.1 Sustainability

- Trend: 60% of factories now use recycled or organic materials, increasing costs by 5–10% but meeting EU and US eco-standards.

- Example: Arlisman’s 600,000 organic garments in 2024 reduced water usage by 25%.

4.2 Advanced Technology

- Trend: Adoption of 3D design (CLO3D), laser cutting, and automated sewing reduces production time by 20–30%.

- Example: BOWINS’ CAD/CAM systems enhance precision by 20%.

4.3 Low MOQ and Customization

- Trend: Factories like Appareify and Lezhou offer MOQs as low as 200–300, supporting startups and e-commerce brands.

- Example: Appareify’s 10-day sampling supports fast-fashion cycles.

4.4 Workwear Demand

- Trend: High-visibility and flame-retardant workwear demand grew by 8% in 2024, driven by construction and industrial sectors.

- Example: Lezhou’s ANSI-compliant workwear exports rose by 15%.

4.5 E-Commerce Growth

- Trend: 60% of apparel sales occur online, with factories partnering with Amazon and Alibaba for direct-to-consumer models.

- Example: Pattern Solution’s 2023 e-commerce exports grew by 10%.

5. How to Choose the Right Clothing Factory

Selecting a Chinese clothing factory requires evaluating your brand’s needs, budget, and quality expectations. Below are key considerations, supported by insights from SourcingYuan and JingSourcing.

5.1 Product Specialization

- Hunting/Workwear: Choose BOWINS or Legend for high-performance, durable apparel.

- Sportswear: Appareify or Lezhou excel in moisture-wicking, stretch fabrics.

- Fashion: Pattern Solution or Arlisman for custom dresses and men’s wear.

5.2 Production Capacity and MOQ

- Large Orders: Appareify’s 400,000 pieces/month suits high-volume brands.

- Small Orders: Lezhou or Appareify offer MOQs as low as 200–300.

5.3 Certifications and Quality

- Ensure ISO 9001, BSCI, or Oeko-Tex certifications for quality and ethical standards.

- Example: BOWINS’ bluesign certification ensures eco-friendly production.

5.4 Lead Time and Logistics

- Fast Delivery: Appareify’s 10–45-day lead time suits fast-fashion brands.

- Global Shipping: BOWINS’ Cambodia facility reduces tariffs by 10–15%.

5.5 Sustainability

- Prioritize factories like Arlisman (60% recycled materials) for eco-conscious brands.

Pro Tip: Request samples to evaluate fabric quality, stitching, and fit before bulk orders. Use sourcing agents like JingSourcing for factory audits and quality control.

6. Cost-Saving Tips for Sourcing from China

- Negotiate Bulk Pricing: Order 10,000+ pieces to reduce per-unit costs by 10–20%.

- Simplify Designs: Avoid complex patterns to lower customization costs by $1–$3 per piece.

- Use Local Fabrics: Source materials from ZhongDa Fabric Market to save 5–10%.

- Leverage Tariffs: Partner with BOWINS’ Cambodia facility for tariff-free exports.

- Plan Ahead: Order 90 days in advance to avoid peak-season delays and price hikes.

7. Final Thoughts

China’s clothing factories, led by Taian BOWINS Garment Co., Ltd., Taian Legend Garment Co., Ltd., and others like Appareify and Arlisman, offer unmatched quality, scalability, and innovation in the USD 1.5 trillion apparel market. With production capacities ranging from 50,000 to 400,000 pieces monthly, advanced technologies like 3D prototyping, and sustainable practices using up to 60% recycled materials, these manufacturers cater to diverse needs—from hunting and workwear to sportswear and fashion. By evaluating product specialization, certifications, and MOQs, and leveraging trade fairs or sourcing agents, brands can secure reliable partners. As the industry grows toward USD 2.69 billion by 2033, partnering with these top factories ensures cost efficiency, quality, and market success.

Contact Taian BOWINS Garment to start your sourcing journey today.