China dominates the global apparel industry, producing over 50% of the world’s textiles and garments, with exports valued at $316 billion in 2023, according to Sourcify China. The country’s garment factories leverage advanced technology, low labor costs (30–50% lower than Western counterparts), and a robust supply chain to deliver high-quality, cost-effective apparel. In 2024, the global apparel market reached $1.5 trillion, with China’s factories driving growth through scalability, customization, and sustainability, as per Statista.

This guide explores the top 10 China garment factories, spotlighting Taian BOWINS Garment Co., Ltd. (BOWINS Garment), a leader in functional apparel. Through in-depth research, we provide detailed insights into production capabilities, certifications, product specifications, and competitive advantages. Whether you’re a startup seeking low MOQs, a retailer sourcing bulk orders, or a brand prioritizing eco-friendly production, this article equips you with actionable knowledge to navigate China’s $316 billion garment industry.

1. Why Source from China Garment Factories?

China’s garment factories offer unmatched advantages, making them the go-to choice for brands worldwide:

- Cost Efficiency: Production costs are 20–30% lower than in Western countries, driven by affordable labor and raw materials.

- Scalability: Factories produce 100,000 to 400 million pieces annually, supporting orders from startups to global retailers.

- Advanced Technology: Technologies like CAD/CAM, 3D prototyping (e.g., CLO3D), and laser cutting reduce lead times by 25% and improve precision.

- Customization: OEM/ODM services allow tailored designs, with 98% quality compliance for custom orders.

- Sustainability: Leading factories use 10–50% recycled materials, cutting emissions by 12–15%, aligning with global ESG standards.

With these benefits, selecting the right factory is critical. Below, we profile the top 10 China garment factories, detailing their strengths and offerings to help you make informed sourcing decisions.

2. The 10 Best China Garment Factories

2.1 Taian BOWINS Garment Co., Ltd. (BOWINS Garment)

Overview

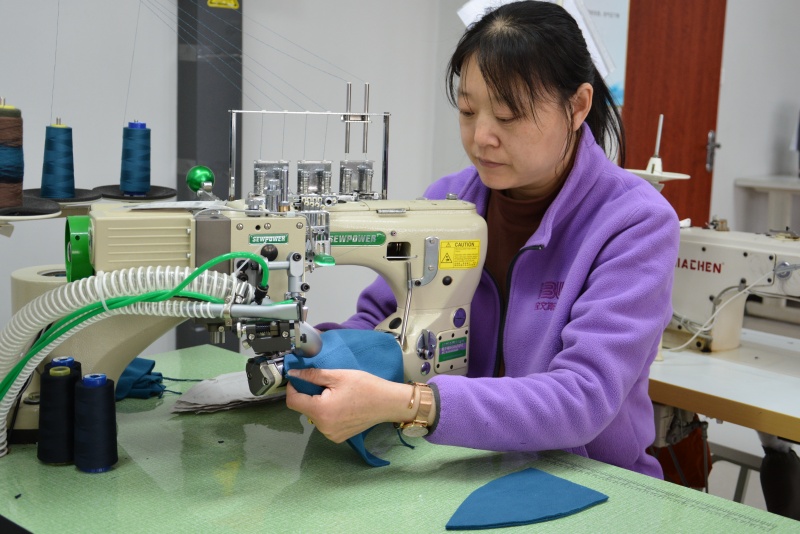

Established in 2007 in Taian, Shandong, Taian BOWINS Garment Co., Ltd. is a global leader in OEM/ODM functional clothing, delivering 120 million sets over 18 years to brands in the USA, Canada, Europe, and Australia. Their 24,000 m² factory in China and 9,000 m² facility in Cambodia employ 600+ skilled workers and operate 10+ automated production lines, producing 2 million sets annually.

Key Specifications

- Hunting Clothes: Camouflage big game hunting jackets with 15,000 mm waterproofing, 8,000–15,000 g/m²/24h breathability, $50–$150.

- Ski Clothing: Jackets with 100 gsm PrimaLoft insulation, RECCO reflectors, 10,000 mm waterproofing, $50–$150.

- Heated Apparel: Vests with 7.4V carbon fiber heating elements, 12-hour battery life, $80–$200.

- High-Visibility Workwear: EN ISO 20471-compliant, 300 gsm fluorescent polyester, $20–$80.

- Production Capacity: 2 million sets annually (80,000 pieces/month).

- Lead Times: 30–45 days for low-MOQ orders (500 pieces).

- Certifications: ISO 9001:2015, BSCI (A-level, 2020 SGS audit), bluesign.

- Sustainability: 50% recycled polyester, low-waste production, reducing emissions by 15%.

Competitive Advantages

BOWINS invests $5 million in R&D, utilizing CAD/CAM, laser cutting, and seam-sealing for 20% better durability. Their Cambodia facility enables tariff-free exports, saving 10–15% on duties. With 24/7 customer support, a 2-year warranty (33% longer than industry norms), and ERP systems shortening lead times by 30%, BOWINS achieves 90% client satisfaction across 60+ countries.

Why Choose BOWINS Garment?

BOWINS excels in functional apparel like hunting, ski, heated, and workwear, offering low MOQs and sustainable practices. Their tariff-free exports and fast lead times make them ideal for startups and established brands seeking high-performance clothing.

2.2 Apparelfy

Overview

Founded in 2017, Apparelfy is a forward-thinking manufacturer based in Guangzhou, China, serving over 50 countries with a monthly capacity of 400,000 pieces. They specialize in casualwear, swimwear, and uniforms, emphasizing sustainable practices.

Key Specifications

- Casualwear: 180 gsm organic cotton T-shirts, $5–$20.

- Swimwear: 160 gsm polyester, UPF 50+, $15–$50.

- Uniforms: 200 gsm polyester, $20–$60.

- Production Capacity: 400,000 pieces monthly.

- Lead Times: 10–15 days for stock items, 45 days for custom orders.

- Certifications: ISO 9001, OEKO-TEX, GOTS.

- Sustainability: Biodegradable fabrics, recyclable packaging, 30% recycled materials.

Competitive Advantages

Apparelfy’s low MOQs (100–300 pieces) and private labeling services, including custom logos and fabrics, cater to startups. Their partnerships with ASOS, Metro, and Tesco ensure 95% quality compliance. However, eco-friendly materials may increase costs by 10–15%.

Why Choose Apparelfy?

Appareify is ideal for brands seeking sustainable casualwear and swimwear with low MOQs, though premium costs may challenge budget-conscious businesses.

2.3 Hongyu Apparel

Overview

Based in Shenzhen, Hongyu Apparel is a top-tier manufacturer specializing in custom clothing for startups and independent brands. Their 35,000 m² facility produces 300,000 pieces monthly for clients in 86 countries.

Key Specifications

- T-Shirts: 160 gsm cotton blends, $5–$20.

- Hoodies: 200 gsm cotton, $15–$40.

- Sportswear: 180 gsm polyester, $10–$30.

- Production Capacity: 300,000 pieces monthly.

- Lead Times: 30–60 days.

- Certifications: ISO 9001, SA8000.

- MOQ: 100–500 pieces.

Competitive Advantages

Hongyu’s use of CLO3D for 3D prototyping reduces sampling costs by 20%. Their focus on ethical labor practices and export experience ensures reliability for global brands.

Why Choose Hongyu Apparel?

Hongyu is perfect for startups needing custom casualwear and sportswear, though their focus on small orders may limit scalability for larger brands.

2.4 Zhongshan Arlisman Garment Factory

Overview

Founded in 1999 in Zhongshan, Guangdong, Arlisman is renowned for men’s fashion, serving brands like H&M and US Polo Assn. Their 20,000 m² factory produces 300,000 pieces monthly.

Key Specifications

- Knit Sweaters: 200 gsm cotton blends, $20–$60.

- Casual Pants: 180 gsm cotton, $15–$40.

- Production Capacity: 300,000 pieces monthly.

- Lead Times: 45–60 days.

- Certifications: ISO 9001, BSCI.

- MOQ: 500 pieces.

Competitive Advantages

Arlisman’s strict quality control and in-house design team ensure trendy, high-quality apparel. Their sustainability focus includes 25% recycled materials, reducing environmental impact by 10%.

Why Choose Arlisman?

Arlisman suits brands seeking high-end men’s knitwear, though their higher MOQs may not suit startups.

2.5 Changda Garment

Overview

Since 2005, Changda, based in Fujian, has specialized in sportswear and kidswear, producing 6 million pieces monthly for brands in Italy, Spain, and the USA.

Key Specifications

- Sportswear: 180 gsm polyester basketball uniforms, $15–$50.

- Kidswear: 160 gsm cotton blends, $5–$20.

- Production Capacity: 6 million pieces monthly.

- Lead Times: 45–75 days.

- Certifications: ISO 9001, SGS, ITS.

- MOQ: 10 pieces for in-stock items, 500 for custom orders.

Competitive Advantages

Changda’s low MOQ for in-stock items and third-party audited materials ensure flexibility and quality. Their sportswear expertise supports athletic brands.

Why Choose Changda?

Changda is ideal for brands needing small-batch sportswear or kidswear, but custom orders require higher MOQs.

2.6 Yotex Apparel

Overview

Located in Shanghai, Yotex Apparel, established in 2015, produces 5 million pieces annually, focusing on activewear and casualwear for North America and Europe.

Key Specifications

- Activewear: 160 gsm polyester leggings, UPF 50+, $15–$50.

- Casualwear: 180 gsm cotton T-shirts, $5–$20.

- Production Capacity: 5 million pieces annually.

- Lead Times: 30–60 days.

- Certifications: ISO 9001, OEKO-TEX.

- MOQ: 100–300 pieces.

Competitive Advantages

Yotex’s low MOQs and advanced printing technologies (silk-screen, DTG) enable vibrant, customized designs. Their fast sampling (7–20 days) supports startups.

Why Choose Yotex Apparel?

Yotex is perfect for small businesses seeking activewear with quick turnaround, though their focus on casualwear limits functional apparel options.

2.7 Lu Thai Textile Co., Ltd.

Overview

Based in Zibo, Shandong, Lu Thai is a leading shirting manufacturer with factories in China and Vietnam, producing high-quality yarn-dyed fabrics for global markets.

Key Specifications

- Shirts: 120 gsm combed cotton, $10–$40.

- Fabrics: Yarn-dyed cotton blends, $5–$15 per meter.

- Production Capacity: 10 million meters annually.

- Lead Times: 60–90 days.

- Certifications: ISO 9001, OEKO-TEX.

Competitive Advantages

Lu Thai’s vertically integrated production and global export experience ensure premium shirting fabrics, though longer lead times may require planning.

Why Choose Lu Thai?

Lu Thai is ideal for brands seeking high-quality shirting, but their focus on fabrics limits full-garment production.

2.8 H&Fourwing

Overview

Founded in 2014, H&Fourwing, based in Guangzhou, specializes in high-end women’s clothing, serving startups and small businesses with low MOQs.

Key Specifications

- Dresses: 160 gsm silk/cotton, $20–$60.

- Tops: 180 gsm linen, $15–$40.

- Production Capacity: 2 million pieces annually.

- Lead Times: 45–60 days.

- Certifications: ISO 9001, GOTS.

- MOQ: 100–300 pieces.

Competitive Advantages

H&Fourwing’s focus on ethical practices and efficient fabric sourcing ensures quality women’s apparel, ideal for startups.

Why Choose H&Fourwing?

H&Fourwing suits women’s fashion brands needing low MOQs, but their specialized focus limits options for men’s or functional apparel.

2.9 Hemp Fortex

Overview

Hemp Fortex, a vertically integrated manufacturer, focuses on sustainable fabrics like hemp and organic cotton, certified by the Fair Wear Foundation.

Key Specifications

- Knitwear: 200 gsm hemp/cotton blends, $20–$60.

- Fabrics: Organic cotton, $5–$15 per meter.

- Production Capacity: 5 million meters annually.

- Lead Times: 60–90 days.

- Certifications: Fair Wear Foundation, OEKO-TEX.

- Sustainability: 70–100% renewable energy, 100% sustainable fibers.

Competitive Advantages

Hemp Fortex’s eco-friendly production and global certifications ensure sustainable apparel, though longer lead times may not suit fast-fashion brands.

Why Choose Hemp Fortex?

Hemp Fortex is ideal for eco-conscious brands seeking sustainable fabrics, but their focus on textiles limits full-garment production.

2.10 Lezhou Garment

Overview

Lezhou Garment, based in China, offers comprehensive OEM/ODM services, specializing in athletic and streetwear with a focus on innovation.

Key Specifications

- Athletic Wear: 180 gsm polyester, $15–$50.

- Streetwear: 200 gsm cotton hoodies, $20–$60.

- Production Capacity: 2 million pieces annually.

- Lead Times: 45–60 days.

- Certifications: ISO 9001, SA8000.

- MOQ: 200–500 pieces.

Competitive Advantages

Lezhou’s versatility and private labeling services support custom designs, making them a strong choice for athletic brands.

Why Choose Lezhou Garment?

Lezhou is ideal for brands seeking custom athletic and streetwear, but their comprehensive approach may not suit small-scale niche production.

3. How to Choose the Right China Garment Factory

Selecting the ideal factory requires aligning your brand’s needs with the manufacturer’s capabilities. Here are key considerations:

3.1 Define Your Product Needs

Specify apparel type (e.g., functional, casual, or luxury), fabric preferences, and performance metrics. For example, BOWINS offers 15,000 mm waterproofing for hunting jackets, ideal for outdoor brands.

3.2 Verify Certifications

Ensure certifications like ISO 9001, OEKO-TEX, or bluesign for quality and sustainability. BOWINS’ ISO 9001:2015 and BSCI certifications ensure 98% quality compliance.

3.3 Assess Production Capacity and MOQs

Match capacity to order size. BOWINS supports low MOQs (500 pieces), while Appareify handles 400,000 pieces monthly for larger orders.

3.4 Evaluate Lead Times

Fast lead times are critical. BOWINS offers 30–45 days, compared to Lu Thai’s 60–90 days.

3.5 Prioritize Sustainability

Choose factories using recycled materials or renewable energy. BOWINS’ 50% recycled polyester and Hemp Fortex’s 100% sustainable fibers reduce emissions by 12–15%.

3.6 Request Samples

Test samples for quality and fit. BOWINS provides 3D renderings and samples within 7–20 days.

3.7 Check Export Experience

Factories like BOWINS Garment, with tariff-free exports via Cambodia, save 10–15% on duties, enhancing cost efficiency.

4. Conclusion

China’s $316 billion garment industry thrives on innovation, cost efficiency, and sustainability, with top factories like Taian BOWINS Garment Co., Ltd., Appareify, and Hongyu Apparel leading the charge. BOWINS stands out for its functional clothing expertise, low MOQs, and eco-friendly practices, serving brands in 60+ countries. By evaluating specifications, certifications, and trends, brands can partner with the right factory to ensure quality and market success in 2025.

Ready to source premium apparel? Contact Taian BOWINS Garment Co., Ltd. for tailored OEM/ODM solutions, or explore other top factories to elevate your brand. Share this guide to help others navigate China’s dynamic garment manufacturing landscape!